Aeronautical IRSS Development

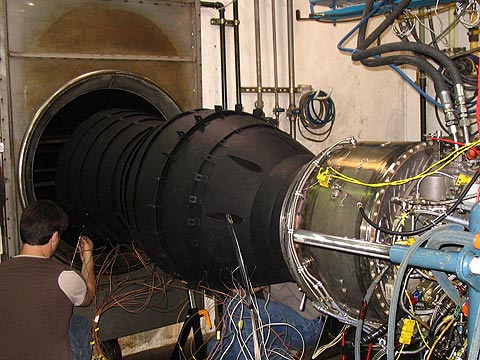

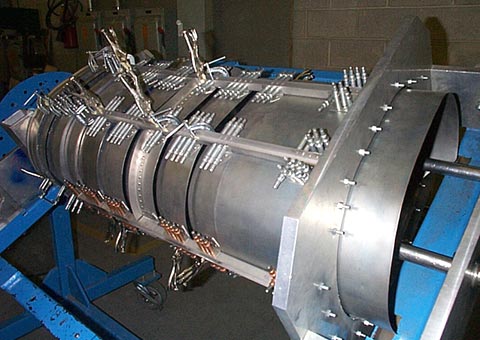

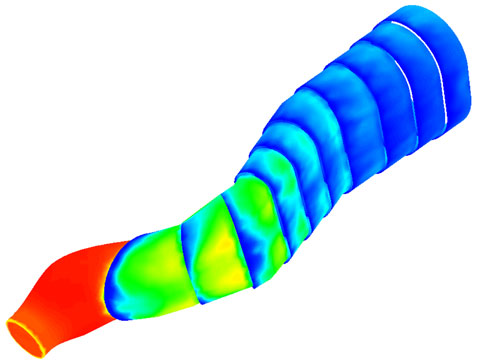

Davis possesses or has access to all the design, manufacturing, and test facilities required to quickly develop IR suppressors for any aircraft type. Modern Computational Fluid Dynamics (CFD), structural analysis, IR signature prediction tools, and specialized simulation codes developed by Davis, allow for the efficient development of high performance and robust designs. Davis also maintains a Hot Gas Wind Tunnel (HGWT) on site, which is able to simulate engine exhaust flow conditions, and is used to test early prototype suppressor designs. In each design, Davis takes into consideration all the key integration issues like: aircraft vibration spectrum; ease of installation; maintenance access; fluid flows in and around the engine; and interoperability with other systems on the aircraft.

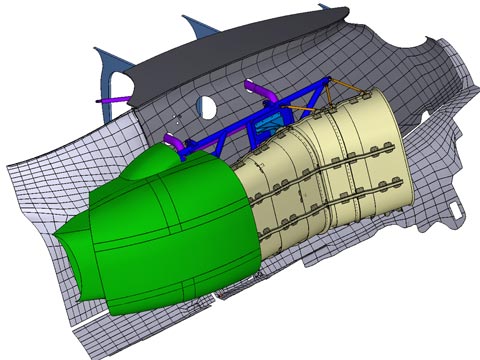

- 3D aircraft integration model of AS332 IRSS

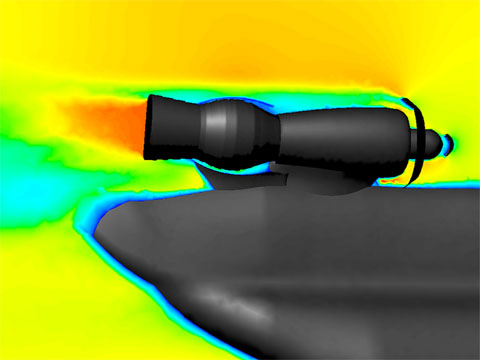

- CFD analysis results of internal flow

- CFD analysis results of external flow