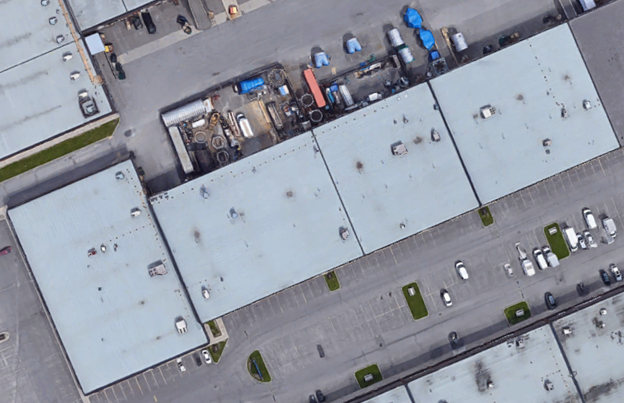

Davis Facilities and Equipment

• 2600m (26000 ft 2) plant

• Grade level and loading dock access

• Access doors 4.27m wide (14ft) x 4.88m high (16ft)

• Hot Gas Wind Tunnel for model testing

• Material handling equipment to 7.6 tonnes (16000 lbs.)

• A-Frames, jib and overhead cranes

• CNC Machine

• Full range of shop tooling including cutting and welding equipment for ferrous and non ferrous metals

• Welding:

- GMAW and FCAW welding machines to 400A

- GTAW welding machine to 300A

- Resistant Spot welding

- Resistant Seam welding

- Capacitor Discharge Stud Welding

- Weld Manipulator and Seam Tracker Machine

- Weld Machine Calibration Load Bank

- Weld Bend Test Fixture

• Welding positioners - 10,000 lb. capacity

• Forming and Cutting:

- Plate shear 1/2 in. x 10ft, mild steel capacity

- Pinch type forming rolls 1/4 in. x 10ft, stainless steel capacity

- Press brake 12 ft x 300-ton capacity

- Sheet metal forming (English wheel, hammer machines, stretch forming)

- CNC Machine

- Plasma and Laser cutting

• Special Processes:

-Non-Destructive Testing

✓ Penetrant Testing

✓ Magnetic Particle Testing

✓ Positive Material Identification Testing

✓ Ultrasonic Thickness Measurement

- Glass beading

- Stress relieving

- Machining (milling machines, lathe)

- Riveting

- Passivation

- Electro Polish

- Painting

- Primer Coating

- Hardness Testing

- Water Break Testing

- Copper Sulfate Testing